What does this standard cover and is it relevant to me?

The Occupational Safety and Health Administration (OSHA) Subpart CC refers to the regulations related to cranes and derricks in construction. Specifically, 29 CFR 1926.1400 through 1926.1442 outlines the safety requirements for cranes and derricks used in construction activities. These regulations are designed to ensure the safe operation of cranes and derricks on construction sites, with a focus on protecting workers from potential hazards.

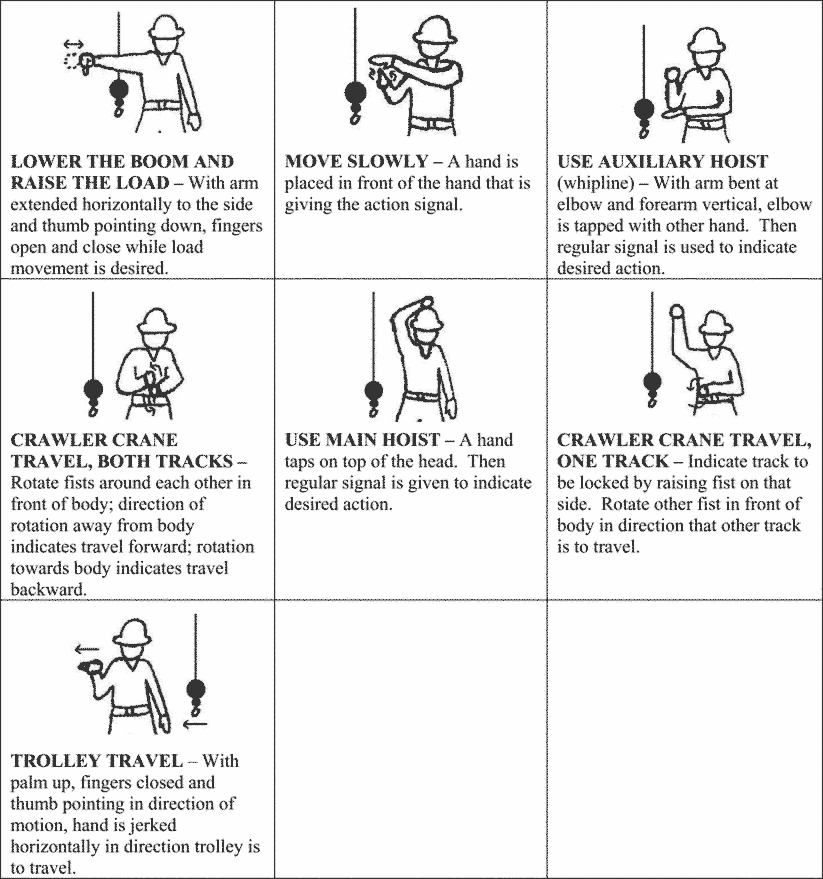

Appendix A to Subpart CC of Part 1926—Standard Hand Signals

Appendix B to Subpart CC of Part 1926--Assembly/Disassembly: Sample Procedures for Minimizing the Risk of Unintended Dangerous Boom Movement

1. Section 1926.1404(f)(1) provides that when pins (or similar devices) are being removed, employees must not be under the boom, jib, or other components, except where the requirements of § 1926.1404(f)(2) are met. The exception in § 1926.1404(f)(2) applies when the employer demonstrates that site constraints require one or more employees to be under the boom, jib, or other components when pins (or similar devices) are being removed. In such a situation, the A/D director must implement procedures that minimize the risk of unintended dangerous movement and minimize the duration and extent of exposure under the boom.

The following scenario is an example of how the exception applies: A boom cannot be disassembled on the ground because of aboveground piping (as might be found, for example, in an oil refinery) that precludes lowering the boom to the ground. The boom must therefore be disassembled in the air, and the employees who remove the pins must perform that work from an aerial lift whose base is positioned on one side (the near side) of the boom. To gain access to the pins on the far side, the aerial lift basket must move under the boom, since, due to lack of room, the aerial lift cannot be repositioned on the far side. Due to lack of room, the aerial lift cannot be repositioned on the far side, so the aerial basket must move under the boom to gain access to the pins on the far side.

To minimize the risk of unintended dangerous movement while the pins are removed, the A/D director uses an assist crane that is rigged to support the boom section that is being detached, using particular care to ensure that the section end that is near the employee(s) removing the pins is well supported. The duration and extent of exposure is minimized by removing the far side pins first, moving the aerial lift basket as soon as possible to the near side so that the employees are no longer under the boom, and then removing the near side pins.

2. Section 1926.1404(h)(6)(i) provides that, during assembly/disassembly, the center of gravity of the load must be identified if that is necessary for the method used for maintaining stability. Section 1926.1404(h)(6)(ii) states that, where there is insufficient information to accurately identify the center of gravity, measures designed to prevent unintended dangerous movement resulting from an inaccurate identification of the center of gravity must be used.

An example of the application of § 1926.1404(h)(6)(ii) is as follows: The boom is assembled by lowering boom sections sequentially into place using an assist crane. The A/D director's plan is to keep the boom sections stable while they are lowered into place by attaching the assist crane hoist line above the center of gravity of each section. However, in assembling the non-symmetrical top section of the boom, the A/D director is not able to determine where to attach the assist crane hoist line so that it is above the center of gravity. In this situation, before raising the section, all personnel are kept clear of the section and the section is first raised a few inches to determine whether it tips when raised (if it did tip, it would indicate it is not rigged over the center of gravity). If this occurs, the hoist line is repositioned and the procedure repeated (with employees kept clear of the section while it is raised) until the A/D director determines that it is rigged over the center of gravity and can be moved into place without dangerous movement.

Appendix B to Subpart CC of Part 1926--Assembly/Disassembly: Sample Procedures for Minimizing the Risk of Unintended Dangerous Boom Movement

1. Section 1926.1404(f)(1) provides that when pins (or similar devices) are being removed, employees must not be under the boom, jib, or other components, except where the requirements of § 1926.1404(f)(2) are met. The exception in § 1926.1404(f)(2) applies when the employer demonstrates that site constraints require one or more employees to be under the boom, jib, or other components when pins (or similar devices) are being removed. In such a situation, the A/D director must implement procedures that minimize the risk of unintended dangerous movement and minimize the duration and extent of exposure under the boom.

The following scenario is an example of how the exception applies: A boom cannot be disassembled on the ground because of aboveground piping (as might be found, for example, in an oil refinery) that precludes lowering the boom to the ground. The boom must therefore be disassembled in the air, and the employees who remove the pins must perform that work from an aerial lift whose base is positioned on one side (the near side) of the boom. To gain access to the pins on the far side, the aerial lift basket must move under the boom, since, due to lack of room, the aerial lift cannot be repositioned on the far side. Due to lack of room, the aerial lift cannot be repositioned on the far side, so the aerial basket must move under the boom to gain access to the pins on the far side.

To minimize the risk of unintended dangerous movement while the pins are removed, the A/D director uses an assist crane that is rigged to support the boom section that is being detached, using particular care to ensure that the section end that is near the employee(s) removing the pins is well supported. The duration and extent of exposure is minimized by removing the far side pins first, moving the aerial lift basket as soon as possible to the near side so that the employees are no longer under the boom, and then removing the near side pins.

2. Section 1926.1404(h)(6)(i) provides that, during assembly/disassembly, the center of gravity of the load must be identified if that is necessary for the method used for maintaining stability. Section 1926.1404(h)(6)(ii) states that, where there is insufficient information to accurately identify the center of gravity, measures designed to prevent unintended dangerous movement resulting from an inaccurate identification of the center of gravity must be used.

An example of the application of § 1926.1404(h)(6)(ii) is as follows: The boom is assembled by lowering boom sections sequentially into place using an assist crane. The A/D director's plan is to keep the boom sections stable while they are lowered into place by attaching the assist crane hoist line above the center of gravity of each section. However, in assembling the non-symmetrical top section of the boom, the A/D director is not able to determine where to attach the assist crane hoist line so that it is above the center of gravity. In this situation, before raising the section, all personnel are kept clear of the section and the section is first raised a few inches to determine whether it tips when raised (if it did tip, it would indicate it is not rigged over the center of gravity). If this occurs, the hoist line is repositioned and the procedure repeated (with employees kept clear of the section while it is raised) until the A/D director determines that it is rigged over the center of gravity and can be moved into place without dangerous movement.

Appendix C to Subpart CC of Part 1926 - Operator Certification: Written Examination: Technical Knowledge Criteria

This appendix contains information for employers, accredited testing organizations, auditors and government entities developing criteria for a written examination to test an individual's technical knowledge relating to the operation of cranes.

(a) General technical information.

(1) The functions and limitations of the crane and attachments.

(2) Wire rope:

(i) Background information necessary to understand the inspection and removal from service criteria in § 1926.1413 and § 1926.1414.

(ii) Capacity and when multi-part rope is needed.

(iii) Relationship between line pull and safe working load.

(iv) How to determine the manufacturer's recommended rope for the crane.

(3) Rigging devices and their use, such as:

(i) Slings.

(ii) Spreaders.

(iii) Lifting beams.

(iv) Wire rope fittings, such as clips, shackles and wedge sockets.

(v) Saddles (softeners).

(vi) Clamps (beams).

(4) The technical limitations of protective measures against electrical hazards:

(i) Grounding.

(ii) Proximity warning devices.

(iii) Insulated links.

(iv) Boom cages.

(v) Proximity to electric power lines, radii, and microwave structures.

(5) The effects of load share and load transfer in multi-crane lifts.

(6) Basic crane terms.

(7) The basics of machine power flow systems.

(i) Mechanical.

(ii) Electrical.

(iii) Pneumatic.

(iv) Hydraulic.

(v) Combination.

(8) The significance of the instruments and gauge readings.

(9) The effects of thermal expansion and contraction in hydraulic cylinders.

(10) Background information necessary to understand the requirements of pre-operation and inspection.

(11) How to use the safety devices and operational aids required under § 1926.1415 and § 1926.1416.

(12) The difference between duty-cycle and lifting operations.

(13) How to calculate net capacity for every possible configuration of the equipment using the manufacturer's load chart.

(14) How to use manufacturer-approved attachments and their effect on the equipment.

(15) How to obtain dimensions, weight, and center of gravity of the load.

(16) The effects of dynamic loading from:

(i) Wind.

(ii) Stopping and starting.

(iii) Impact loading.

(iv) Moving with the load.

(17) The effect of side loading.

(18) The principles of backward stability.

(b) Site information.

(1) How to identify the suitability of the supporting ground/surface to support the expected loads of the operation. Elements include:

(i) Weaknesses below the surface (such as voids, tanks, loose fill).

(ii) Weaknesses on the surface (such as retaining walls, slopes, excavations, depressions).

(2) Proper use of mats, blocking/cribbing, outriggers, stabilizers, or crawlers.

(3) Identification of site hazards such as power lines, piping, and traffic.

(4) How to review operation plans with supervisors and other workers (such as the signal person), including how to determine working height, boom length, load radius, and travel clearance.

(5) How to determine if there is adequate room for extension of crawlers or outriggers/stabilizers and counterweights.

(c) Operations.

(1) How to pick, carry, swing and place the load smoothly and safely on rubber tires and on outriggers/stabilizers or crawlers (where applicable).

(2) How to communicate at the site with supervisors, the crew and the signal person.

(3) Proper procedures and methods of reeving wire ropes and methods of reeving multiple-part lines and selecting the proper load block and/or ball.

(4) How to react to changes in conditions that affect the safe operation of the equipment.

(5) How to shut down and secure the equipment properly when leaving it unattended.

(6) Know how to apply the manufacturer's specifications for operating in various weather conditions, and understand how environmental conditions affect the safe operation of the equipment.

(7) How to properly level the equipment.

(8) How to verify the weight of the load and rigging prior to initiating the lift.

(9) How to determine where the load is to be picked up and placed and how to verify the radii.

(10) Know basic rigging procedures.

(11) How to carry out the shift inspection required in this subpart.

(12) Know that the following operations require specific procedures and skill levels:

(i) Multi-crane lifts. (ii) Hoisting personnel.

(iii) Clamshell/dragline operations.

(iv) Pile driving and extracting.

(v) Concrete operations, including poured-in-place and tilt-up.

(vi) Demolition operations.

(vii) Operations on water.

(viii) Magnet operations.

(ix) Multi-drum operations.

(13) Know the proper procedures for operating safely under the following conditions:

(i) Traveling with suspended loads.

(ii) Approaching a two-block condition.

(iii) Operating near power lines.

(iv) Hoisting personnel.

(v) Using other than full outrigger/crawler or stabilizer extensions.

(vi) Lifting loads from beneath the surface of the water.

(vii) Using various approved counterweight configurations.

(viii) Handling loads out of the operator's vision ("operating in the blind").

(ix) Using electronic communication systems for signal communication.

(14) Know the proper procedures for load control and the use of hand-held tag lines.

(15) Know the emergency response procedure for:

(i) Fires.

(ii) Power line contact.

(iii) Loss of stability.

(iv) Control malfunction.

(v) Two-blocking.

(vi) Overload.

(vii) Carrier or travel malfunction.

(16) Know how to properly use outriggers and stabilizers in accordance with manufacturer specifications.

(d) Use of load charts.

(1) Know the terminology necessary to use load charts.

(2) Know how to ensure that the load chart is the appropriate chart for the equipment in its particular configuration and application.

(3) Know how to use load charts. This includes knowing:

(i) The operational limitations of load charts and footnotes.

(ii) How to relate the chart to the configuration of the crane, crawlers, or outriggers/stabilizers extended or retracted, jib erected or offset, and various counterweight configurations.

(iii) The difference between structural capacity and capacity limited by stability.

(iv) What is included in capacity ratings.

(v) The range diagram and its relationship to the load chart.

(vi) The work area chart and its relationship to the load chart.

(vii) Where to find and how to use the "parts-of-line" information.

(4) Know how to use the load chart together with the load indicators and/or load moment devices.

|

Disclaimer: The information provided above: (i) is intended only as a general educational resource for Users of our Knowledge Base, and is not intended for a specific use in, and does not constitute advice for, a User’s specific situation; and (ii) may no longer be accurate as of the date of a User’s access due to unforeseen changes to regulations, standards or other factors. By accessing our Website and Knowledge Base, you acknowledge and agree that you are solely and exclusively liable and responsible for your actions arising out of the Website and Knowledge Base, and ITI shall have no liability or responsibility therefore. For personalized advisement to your organization, please contact ITI at info@iti.com and we'd be happy to help you. |