Rigging Engineering Training Starts at Age 5

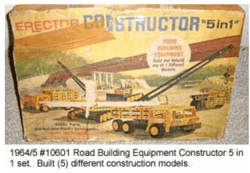

When does formal training, learning, and practical application in regards to crane operations and rigging truly begin? It can be argued that infants start learning when they stack blocks and then knock them over. Preschoolers are able to put parts and pieces together using toys like Legos and K’nex to build a world of creations. Then there are the really lucky kids who had an Erector set. The Meccano (Erector) Set 5 – 395 pieces , combined metal strips, gears, connectors, tools, motors and more to create a jumbo crane, a car ramp, a loading shovel, a car ferry, a moon explorer, and/or a traction engine. The first construction sets were actually created by Frank Hornby in England in 1901 under the name Meccano, though it was A.C. Gilbert who coined the name “Erector,” for the construction set. Meccano is arguably the most popular system worldwide that was ever produced.

, combined metal strips, gears, connectors, tools, motors and more to create a jumbo crane, a car ramp, a loading shovel, a car ferry, a moon explorer, and/or a traction engine. The first construction sets were actually created by Frank Hornby in England in 1901 under the name Meccano, though it was A.C. Gilbert who coined the name “Erector,” for the construction set. Meccano is arguably the most popular system worldwide that was ever produced.

When asked about his career and origins in the crane, rigging and load handling world, Michael Johnson, ITI Senior Instructor, tipped his head back to ponder and responded, “Oh, when I was about five years old.” Michael went on to describe the electric motor that had two gears that drove two winches and how he learned to rig the hook in the block. I’m sure he had no idea at five years old that he would be teaching the intricate details of crane and rigging best practices over half a century later.

Ron Kohner PE, of Landmark Engineering Services, begin his career in crane design and application in 1970. An incredibly well-regarded engineer who has provided consultancy to crane and rigging users for over 30 years, Mr. Kohner participated in the development of the Fundamentals of Rigging Engineering Program, by providing curriculum design and development on a number of courses within the Program. Here are Ron's thoughts on the program:“Congratulations! Your mother would have been proud. For some time now you have been selecting the best crane for a job from a seemingly endless library of load rating charts. You’ve chosen appropriate slings and shackles to develop rigging configurations that provides safe, stable and efficient load rigging arrangements. In spite of the expertise you have acquired in such lift planning, it would be satisfying to understand the “why” of all the chart specifications instead of just the “how”. ITI’s Rigging Engineering courses provide that background. An impressive lineup of lifting industry veterans present students with engineering information and techniques selectively assembled from their decades of experience. There is no other single forum where such a collection of knowledge is available.”

As innovative as the original Erector sets were, the individual components could be bent fairly easily, meaning the fun did not always last forever.  Maybe that is what sparked Michael’s interest in making sure crane, rigging and load handling activities are performed correctly and safely every day. Every career path gets to the point where the only logical way to progress is to increase knowledge. ITI’s Fundamentals of Rigging Engineering was specifically developed for Superintendents, Lift Planners & Engineers around the globe who are charged with conducting advanced load handling and rigging engineering activities.

Maybe that is what sparked Michael’s interest in making sure crane, rigging and load handling activities are performed correctly and safely every day. Every career path gets to the point where the only logical way to progress is to increase knowledge. ITI’s Fundamentals of Rigging Engineering was specifically developed for Superintendents, Lift Planners & Engineers around the globe who are charged with conducting advanced load handling and rigging engineering activities.

The Fundamentals of Rigging and Engineering Program is a comprehensive introduction to the science and art of the engineering behind heavy rigging, lifting, and transport activities. ASME has audited and approved all Courses in ITI’s Fundamentals of Rigging Engineering Program for Continuation Education Units (CEUs) in compliance with IACET (International Association for Continuing Education and Training) Standard and the Program is fully accredited by the Lifting Equipment Engineers Association (LEEA).

A free demo of the program is available here, please visit www.iti.com/riggingengineering or call 360.225.1100 for more details.

COMMENTS